Process Optimization Presentation Template Download

- Techriv

- May 6, 2024

- Entrepreneurship

- 0 Comments

Introduction:

In today’s rapidly evolving business landscape, the quest for efficiency and optimization has become more critical than ever. Organizations must continually seek ways to generate maximum value with minimal resources, ensuring they remain competitive and agile in an increasingly competitive market. Our Process Optimization Presentation is designed to address this challenge head-on, offering a comprehensive toolkit of methodologies and tools to help businesses streamline their operations and drive continuous improvement. From root cause analysis to risk management and continuous improvement techniques, our presentation provides practical insights and customizable templates to empower teams to enhance their processes and achieve optimal results. Join us as we explore the strategies and methodologies that can transform your business operations and unlock new levels of efficiency and success.

Download this presentation:

Download Powerpoint PPT

Download Google Slides

Download Apple Keynote

Preview

Download this presentation:

Download Powerpoint PPT

Download Google Slides

Download Apple Keynote

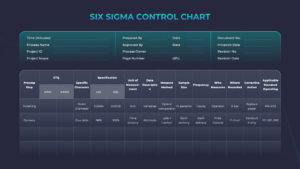

Root Cause Analysis Template

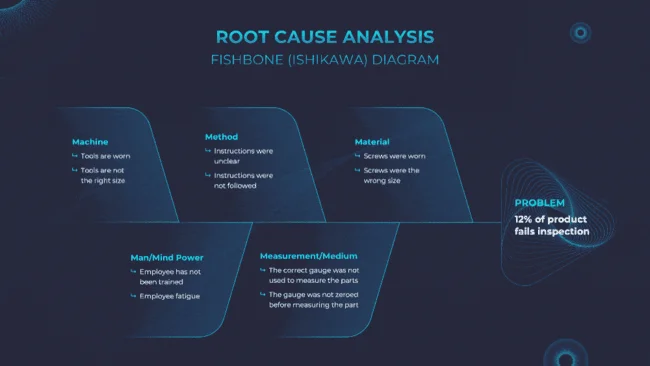

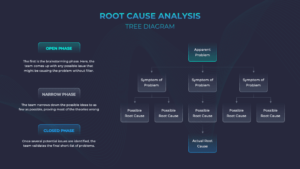

Before diving into process improvement efforts, it’s crucial to identify the root causes of any issues. Our presentation offers tools such as the Fishbone Diagram and the 5 Why’s framework to help project teams pinpoint underlying problems. The Fishbone Diagram breaks down the main problem into individual components, while the 5 Why’s framework takes a top-down approach to uncover deeper issues. By understanding the root causes, teams can develop targeted solutions to drive meaningful change.

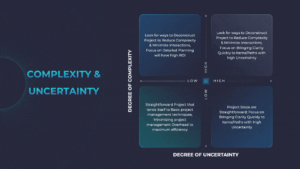

Managing Process Risk

Change always comes with risks, and our presentation includes tools to help businesses effectively manage process risks. From identifying existing risks to anticipating potential future risks, our presentation provides insights into setting realistic expectations and making informed decisions. The Complexity and Uncertainty Matrix helps teams map out the complexity and uncertainty associated with process improvement plans, allowing them to prioritize initiatives and mitigate risks effectively.

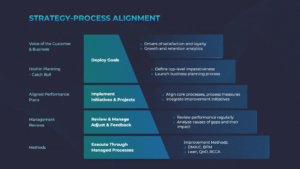

Driving Continuous Improvement

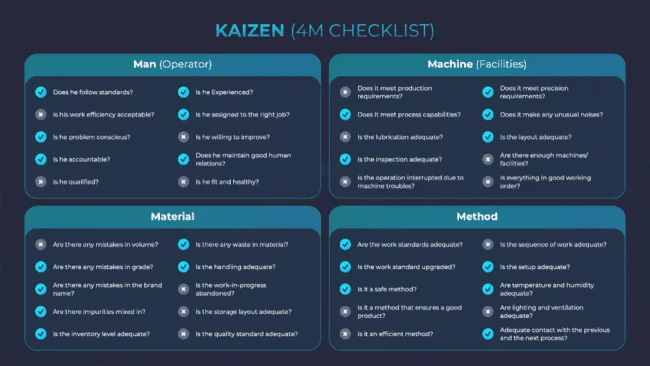

Continuous improvement is at the heart of process optimization, and our presentation offers tools to facilitate ongoing refinement and enhancement. Kaizen, a cornerstone of process improvement, emphasizes continuous incremental changes to achieve better results over time. The 4M checklist provides a structured approach to tracking detailed tasks on the ground, ensuring that all critical components are addressed with clarity and organization. These tools can be integrated into the Toyota Production System (TPS), a comprehensive framework that aligns business goals with process optimization methods to drive successful outcomes.

Download this presentation template:

Download Powerpoint PPT

Download Google Slides

Download Apple Keynote

Kaizen Tools for Continuous Improvement

Kaizen, a Japanese term meaning “change for the better,” is a powerful tool for driving continuous improvement within organizations. Our presentation explores how Kaizen fosters a culture of innovation and efficiency by encouraging small, incremental changes over time. By implementing Kaizen principles, teams can identify opportunities for improvement, engage employees in problem-solving, and ultimately achieve better results. With its emphasis on continuous learning and adaptation, Kaizen empowers organizations to stay ahead of the curve and continuously optimize their processes for maximum efficiency and effectiveness.

Kaizen 4M Checklist PPT

The 4M checklist is a valuable tool for streamlining processes and ensuring that all critical components are addressed. By focusing on Man, Machine, Material, and Method, teams can identify potential areas for improvement and track detailed tasks with clarity and precision. Our presentation provides insights into how the 4M checklist can be integrated into process optimization efforts to drive efficiency and productivity. By leveraging the 4M checklist, organizations can identify bottlenecks, minimize waste, and optimize resource utilization to achieve their goals more effectively.

Embracing the Toyota Production System (TPS)

The Toyota Production System (TPS) is a comprehensive framework that embodies the principles of process optimization and continuous improvement. Our presentation delves into how TPS aligns business goals with process optimization methods, creating a foundation for success. By implementing TPS principles, organizations can streamline operations, eliminate waste, and achieve sustainable growth. With its focus on customer value, employee empowerment, and relentless improvement, TPS provides a roadmap for organizations to thrive in today’s competitive business environment.

Empowering Teams with Andon Boards

Andon boards are visual management tools that empower teams to monitor and improve their processes in real-time. Our presentation explores how Andon boards provide visibility into production status, identify bottlenecks, and facilitate quick problem-solving. By leveraging Andon boards, teams can improve communication, enhance productivity, and drive continuous improvement across the organization. With their intuitive design and user-friendly interface, Andon boards empower teams to take ownership of their work and collaborate more effectively towards common goals.

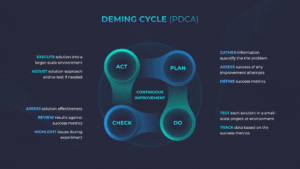

Deming Cycle PPT

The Deming Cycle, also known as PDCA (Plan-Do-Check-Act), is a systematic approach to problem-solving and process improvement. Our presentation outlines how PDCA enables teams to identify opportunities, test solutions, measure results, and make adjustments as needed. By embracing the PDCA cycle, organizations can foster a culture of continuous learning and improvement, driving innovation and success in today’s competitive marketplace. With its iterative nature and focus on data-driven decision-making, PDCA provides a structured framework for organizations to achieve their goals and continuously improve their processes for long-term success.

Process Optimization Template

Process optimization involves the systematic review and improvement of business processes to enhance efficiency, productivity, and overall performance. Our process optimization template provides a structured framework for organizations to analyze their existing processes, identify areas for improvement, and implement changes that drive tangible results.

At the heart of our template is a series of tools and methodologies designed to streamline operations and eliminate waste. From root cause analysis techniques such as the Fishbone Diagram and Five Why’s framework to risk identification methods and continuous improvement strategies like Kaizen and the Deming Cycle (PDCA), our template offers a comprehensive toolkit for process improvement.

Each tool is accompanied by customizable slides and instructions, making it easy for teams to apply these methodologies to their specific challenges and goals. Whether you’re looking to reduce lead times, improve quality, or optimize resource utilization, our process optimization template equips you with the tools and guidance you need to drive meaningful change and achieve sustainable success.

Conclusion:

In conclusion, our Process Optimization Presentation equips businesses with the tools and methodologies they need to streamline processes, mitigate risks, and drive continuous improvement. By identifying root causes, managing process risks, and fostering a culture of continuous improvement, organizations can achieve greater efficiency, productivity, and success. With customizable templates and practical insights, our presentation empowers teams to optimize processes and unlock their full potential in today’s dynamic business environment.

Download Process Optimization Presentation:

Download Powerpoint PPT

Download Google Slides

Download Apple Keynote